Browse Difficult Terrain with Self-confidence: Komatsu Undercarriage Parts Selection Guide

Browse Difficult Terrain with Self-confidence: Komatsu Undercarriage Parts Selection Guide

Blog Article

Boost Productivity With Undercarriage Components and Its Utilizes

Comprehending the complex elements that make up the undercarriage of hefty equipment is important for companies intending to optimize their operational efficiency. From track footwear to idlers and gears, undercarriage parts play an essential function in the efficiency and long life of tools. The calculated utilization of these elements can bring about substantial renovations in productivity and price savings. Let's discover how organizations can harness the power of undercarriage parts to simplify their operations and drive success in an open market.

Significance of Undercarriage Parts

Routine maintenance and timely replacement of undercarriage parts are critical to avoid pricey downtime and make best use of productivity. Damaged undercarriage parts can lead to reduced grip, enhanced fuel consumption, and accelerated wear on other parts of the equipment. By buying high-quality undercarriage parts and adhering to a strict maintenance timetable, operators can enhance the performance of their hefty machinery and prolong its solution life.

Typical Sorts Of Undercarriage Parts

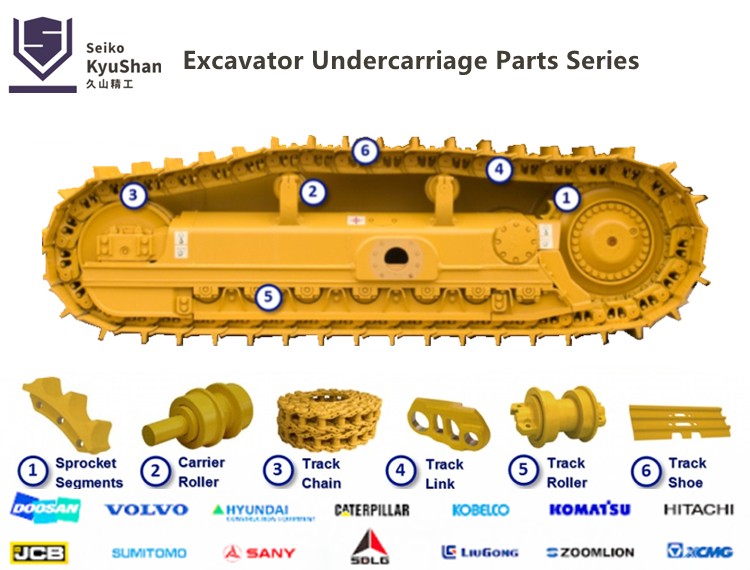

Essential elements essential for the efficient operation of heavy machinery, undercarriage parts play a crucial role in guaranteeing optimal performance and durability of the devices. Some typical kinds of undercarriage parts consist of track chains, track footwear, rollers, idlers, sprockets, and track frameworks. Recognizing the feature and value of these typical undercarriage components is important for maintaining heavy equipment in optimum functioning problem, minimizing downtime, and making best use of efficiency on task sites.

Benefits of Normal Maintenance

Enhancing functional performance and prolonging tools life expectancy, regular maintenance of undercarriage parts is crucial for taking full advantage of heavy machinery efficiency. By adhering to an organized maintenance routine, operators can avoid pricey malfunctions and minimize downtime. Regular evaluations and servicing of undercarriage elements such as tracks, idlers, rollers, and sprockets not only make sure smooth operation however also add to overall security on work websites.

Enhancing Tools Performance

In addition, picking the appropriate undercarriage components for details operating problems is critical. When choosing undercarriage parts, elements such as the kind of surface, workload, and ecological problems should be taken right into factor to consider. Making use of top notch parts that are created to endure the demands of the job can enhance total equipment efficiency and longevity.

Moreover, maintaining undercarriage components well-lubricated and tidy is vital for smooth procedure. Dust, particles, and lack of lubrication can create premature deterioration on look at these guys parts, resulting in reduced efficiency and possible breakdowns. Regular cleaning and lubrication regimens can help avoid these problems and make sure regular equipment efficiency.

Cost-efficient Solutions for Businesses

To optimize undercarriage parts properly and ensure long-term equipment performance, businesses need to focus on cost-efficient remedies that straighten with their functional needs and budget constraints. Buying top notch undercarriage parts can bring about substantial financial savings in the future by lowering downtime, upkeep prices, and the danger of unforeseen equipment failures. One affordable service for companies is to execute a positive upkeep routine that includes normal examinations, lubrication, and timely substitute of damaged undercarriage components. By recognizing and attending to possible problems early, companies can prevent expensive fixings and expand the life expectancy of their tools.

Additionally, businesses can explore alternative undercarriage components such as aftermarket components that meet market requirements and requirements at a lower price than OEM components. By meticulously reviewing their alternatives and partnering with reputable vendors, services can efficiently handle their undercarriage component costs without compromising on efficiency or dependability.

Final Thought

In final thought, undercarriage components play an important duty in enhancing tools performance and efficiency. It is clear that undercarriage components are essential parts for services looking to boost productivity and preserve their tools in optimal problem.

From track footwear to idlers and sprockets, undercarriage parts play a crucial function in the efficiency and like it longevity of equipment.The value of undercarriage components in heavy equipment can not be overemphasized, as they are essential elements that dramatically affect get more the total efficiency and long life of the tools.Essential components necessary for the efficient operation of heavy equipment, undercarriage parts play a vital function in making sure optimum efficiency and long life of the equipment.Enhancing operational efficiency and lengthening tools life-span, normal upkeep of undercarriage components is essential for making best use of hefty equipment efficiency. In addition, organizations can check out alternate undercarriage components such as aftermarket elements that meet sector criteria and specs at a reduced cost than OEM parts.

Report this page